Shape Coefficient#

Shape coefficient describes the behavior of the resulting pressure applied to a surface. It can be interepreted as a resulting pressure coefficient inside a given region.

It allows us to assess how the local pressure at different points inside a region combine themselves.

Definition#

The shape coefficient is a dimensionless form of the resulting pressure signal.

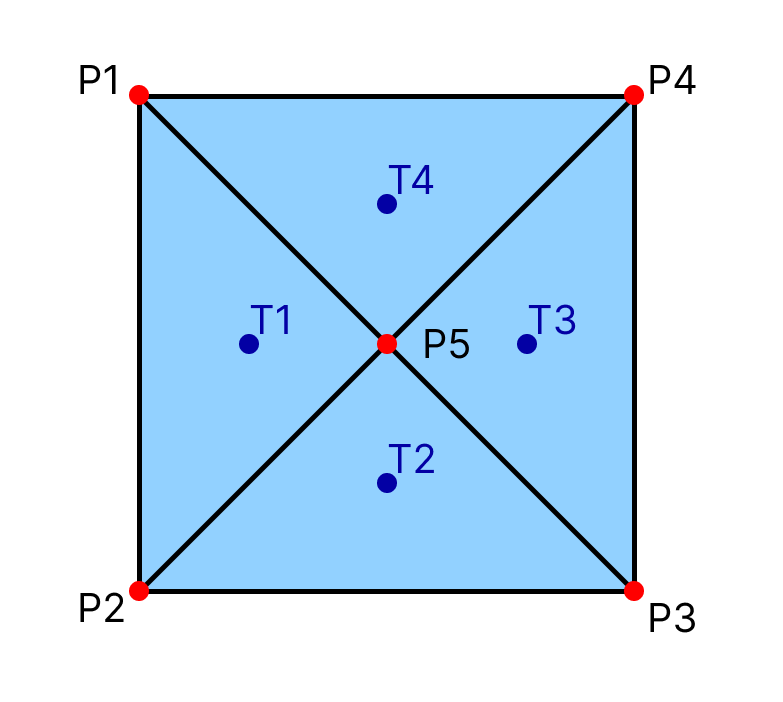

Consider a rectangular surface composed by triangles. At each of its triangles’ center, pressure signals are obtained. However, we can calculate the resulting force by summing the pressure load of each triangle. To do so, pressure is transformed into a force by multiplying by the respective triangle area.

We can define a resulting force for each triangle as:

Even so, we can define a resulting force for the surface, by summing its triangles forces:

Important

Some peaks (minimum or maximum) of the pressure coefficient signal can be cancelled when calculating the shape coefficient.

The shape coefficient is based on the definition of an area of influence. This area is delimited by x, y and z intervals. Each combination of the intervals results in a region.

Note

Check out the concepts section for more information about region and surface definitions.

To calculate the shape coefficient of a given region, the surface triangles which center lies inside this region must be filtered. Then, the resulting force is evaluated for the filtered triangles data. After that, the shape coefficient can be calculated. For the previous example, considering a case where only one region exists:

And we can obatin its maximum, minimum, RMS and average values.

Use Case#

By definition, the shape coefficient is a property of a surface or an area. It is used to evaluate wind loads on primary and secondary structures, such as beans, coating and sealing components.

Structural engineers might use the shape coefficient for wind load evaluation on superficial and long elements.

For smaller components, it is essential to define small intervals for the region definition, which size should be comparable to the component of interest size.

For example, to evaluate the effect of wind pressure on windows, the intervals used for defining the shape coefficient regions should be about the window size, in a way that all triangles that form the window lie inside of this region.

It can also be used to evaluate the resulting wind effect over coating elements, mounted on roofs or walls, such as panels. Or even to evaluate the resulting effect over doors, and calculate the stress over its hinges.

Artifacts#

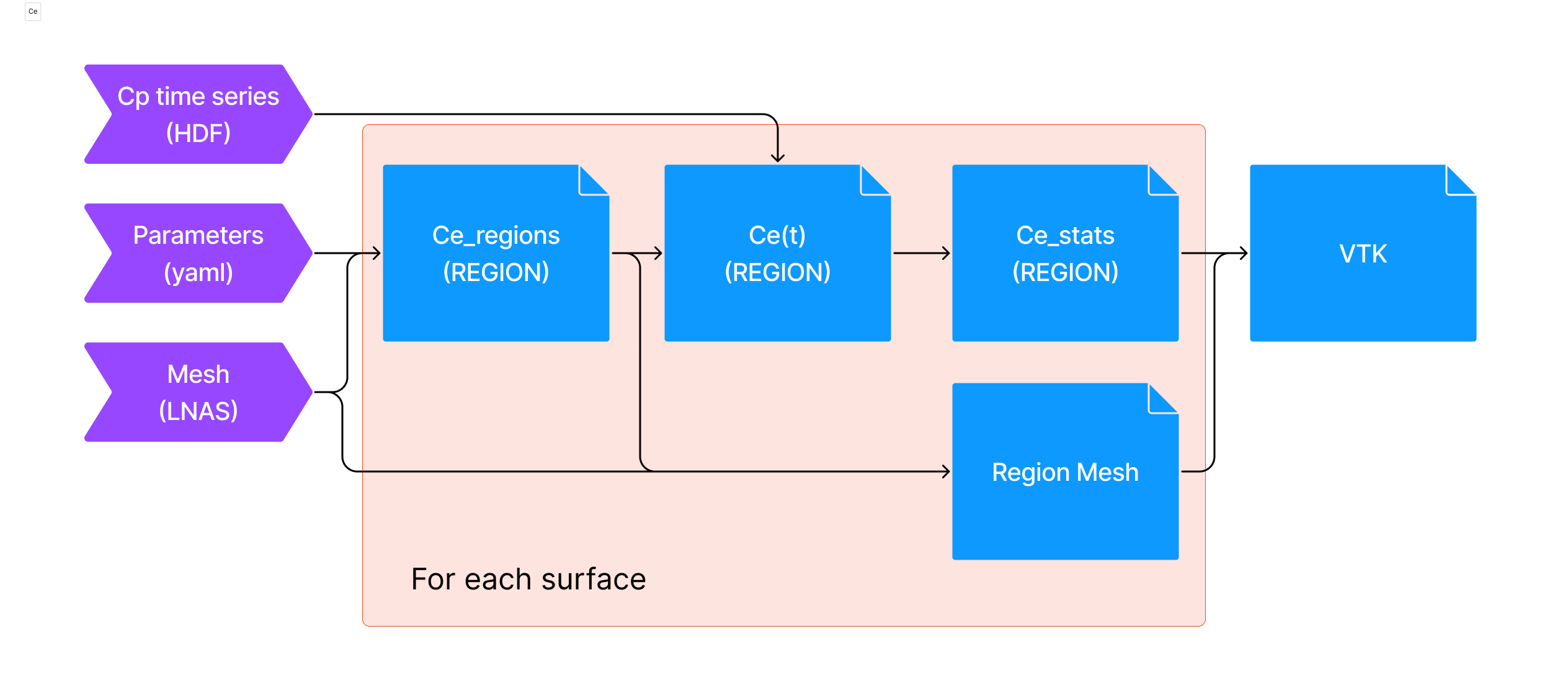

In order to use the shape coefficient module, the user has to provide a set of artifacts:

A lnas file: It contains the information about the mesh.

HDF time series: It contains the pressure coefficient signals indexed by each of the mesh triangles.

Parameters file: It contains the zoning information for defining the bounding area, as well as other configs parameters.

Which outputs the following data:

Dimensionless time series: shape coefficient time series for each region.

Regions: definition of each region generated with its bounds (x_min, x_max), (y_min, y_max), (z_min, z_max), and the region index.

Regions mesh: new mesh generated using the region information and the original mesh.

Statistical results: maximum, minimum, RMS and average values for the shape coefficient time series, for each region.

VTK File: contains the statistical values inside the region mesh (VTK).

An illustration of the shape coefficient module pipeline can be seen below:

Usage#

An example of the parameters file required for calculating the shape coefficient can be seen below:

shape_coefficient:

pattern_1:

zoning:

# Relative path to this file

yaml: "./zoning_params.yaml"

statistics:

- stats: "mean"

- stats: "rms"

- stats: "skewness"

- stats: "kurtosis"

- stats: "mean_eq"

params:

scale_factor: 0.61

- stats: "min"

params:

method_type: "Moving Average"

window_size_interval: 3

full_scale_U_H: 40

full_scale_characteristic_length: 22.4

- stats: "max"

params:

method_type: "Absolute"

# Apply transformations before indexing the regions

transformation:

translation: [0, 0, 0]

rotation: [0, 0, 0]

fixed_point: [0, 0, 0]

# Define a default region rule

global_zoning:

x_intervals: []

y_intervals: []

z_intervals: []

# Optional

no_zoning: [] # Select the surfaces to ignore region mesh generation

# Optional

exclude: [] # Select surfaces to ignore when calculating shape coefficient

# Optional

exceptions:

# Define a specific region rules

zoning1:

x_intervals: []

y_intervals: []

z_intervals: []

surfaces: [] # Surface to overload the default rule

To invoke and run the calculation, the following command can be used:

uv run python -m cfdmod.use_cases.pressure.Ce \

--output {OUTPUT_PATH} \

--cp {CP_SERIES_PATH} \

--mesh {LNAS_PATH} \

--config {CONFIG_PATH}

Or it can be generated together with the pressure data conversion:

uv run python -m cfdmod.use_cases.pressure \

--output {OUTPUT_PATH} \

--cp {CP_SERIES_PATH} \

--mesh {LNAS_PATH} \

--config {CONFIG_PATH} \

--Ce

Another way to run the shape coefficient calculation, is through the notebook

Data format#

Important

All tables for shape coefficient listed below are defined for each of the body’s surfaces, unlike the other coefficients. The idea is to keep the processing for a single surface and not account for unrelated data.

Note

The rule for determining the region_idx is based on the region index and the surface name. Input mesh can have multiple surfaces, and each of them can be applied a specific zoning/region rule. Because of that, region_idx has to be composed by the zoning region index joined by “-” and the surface name. This also guarantee that even if different surfaces lie on the same region, the interpreted region for each of them will be different

Note

For more information about the normalized time scale (\(t^*\)), check the Normalization section

time_idx/region_idx |

Normalized time (\(t^*\)) |

0-Surface 1 |

1-Surface 1 |

|---|---|---|---|

0 |

0.0 |

0.25 |

0.35 |

1 |

1.0 |

0.23 |

0.32 |

region_idx |

max |

min |

mean |

std |

skewness |

kurtosis |

|---|---|---|---|---|---|---|

0-Surface 1 |

1.25 |

0.9 |

1.1 |

0.2 |

0.1 |

0.15 |

1-Surface 1 |

1.15 |

0.95 |

1.13 |

0.19 |

0.11 |

0.13 |

region_idx |

point_idx |

|---|---|

0-Surface 1 |

0 |

1-Surface 1 |

1 |

region_idx |

x_min |

x_max |

y_min |

y_max |

z_min |

z_max |

|---|---|---|---|---|---|---|

0-Surface 1 |

0 |

100 |

0 |

50 |

0 |

20 |

1-Surface 1 |

100 |

200 |

0 |

50 |

0 |

20 |